Home improvement enthusiasts are always on the lookout for efficient and cost-effective ways to enhance their living spaces. One popular option that has gained traction in recent years is the use of DIY spray foam kits. These kits promise a seamless and effective solution for home insulation, but the underlying question remains: can they be used safely at home? Let’s explore this topic in-depth, weighing the benefits against potential risks and safety precautions.

In this article, we will unravel the ins and outs of DIY spray foam kits, shedding light on their applications in home insulation, possible chemical exposures, and essential safety precautions. Homeowners must familiarize themselves with the necessary protective gear and ventilation requirements to ensure a safe application process. Furthermore, as we discuss the importance of understanding toxic fumes and how to manage them effectively, it’s vital for anyone considering this home improvement tool to be adequately informed before diving in.

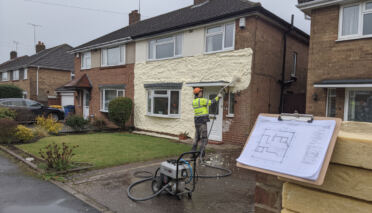

The Basics of DIY Spray Foam Kits

DIY spray foam kits have emerged as a popular choice among homeowners looking to improve energy efficiency and reduce heating and cooling costs. These kits consist of two primary components—the resin and the hardener—that, when mixed, create a foam that expands and hardens once applied. This foam acts as an effective insulator, filling gaps and creating a tight seal to prevent air leakage.

Many homeowners find DIY spray foam kits appealing due to their cost-effectiveness compared to hiring a professional insulation service. With the ability to purchase a kit for a fraction of the price of professional installation, DIY spray foam applications can save money on insulation while providing similar benefits.

Understanding Foam Application

Applying spray foam requires careful attention to detail. It is not merely a hit-or-miss approach; proper technique is vital to achieve optimal results. For instance, before beginning any spray foam project, it’s essential to prepare the application area thoroughly. This preparation includes cleaning and drying surfaces, ensuring there’s no moisture present that could hinder the foam’s bonding capabilities.

Moreover, the correct application method involves starting from the bottom of an area and working upwards, filling gaps rather than over-applying in one go. A common mistake is to spray too thickly in one layer, which can lead to inconsistent insulation performance. Instead, the best approach is to apply thin layers, allowing the foam to expand properly before adding more.

- 🛠️ Prepare the surface: Clean and dry thoroughly.

- 🎯 Start from the bottom: Work upwards to ensure even coverage.

- ✨ Apply thin layers: Avoid over-spraying to ensure proper expansion.

Safety Precautions When Using Spray Foam Kits

While DIY spray foam kits offer numerous benefits, safety should always be the top priority. The application of spray foam involves chemicals that can produce potent fumes, leading to health risks if not handled properly. Before initiating any foam application, homeowners must ensure the area is well-ventilated.

Adequate ventilation ensures that potentially harmful fumes disperse, reducing the risk of chemical exposure. Open windows and doors to enhance airflow, and consider using fans to circulate air effectively. If possible, applying spray foam outdoors can help avoid inhalation of toxic fumes.

Protective Gear is Essential

Before tackling a DIY insulation project, it’s crucial to equip yourself with the right protective gear. This protective gear not only helps safeguard your health but also enhances the overall application experience. Key items include:

- 🧤 Gloves: Wear chemical-resistant gloves to prevent skin irritation.

- 😷 Respirator: Use a respirator mask designed for chemical fumes to avoid inhalation hazards.

- 👓 Safety goggles: Protect your eyes from overspray while working.

Equipping yourself with protective gear is not optional; it’s an essential step in ensuring a safe DIY spray foam experience. Also, remember to read the manufacturer’s guidelines for any specific safety instructions associated with the particular kit you are using.

Potential Health Risks and Chemical Exposure

One of the most significant concerns surrounding DIY spray foam kits is the risk of chemical exposure. The primary chemicals in spray foam are isocyanates, known to cause respiratory problems and other health issues when inhaled. Short-term exposure can lead to symptoms such as coughing, throat irritation, and allergic reactions, while long-term exposure can result in more severe respiratory conditions.

Other components of spray foam can release toxic fumes during application and curing, making it critical to take safety precautions seriously. Depending on how well you ventilate the area and utilize protective gear, exposure levels can vary significantly.

Managing Toxic Fumes Effectively

Managing toxic fumes during the foam application process starts with choosing the right environment. Always strive to work outdoors or in a well-ventilated space. If an indoor project is unavoidable, it is a good idea to have an additional exhaust fan to help filter any stagnant air. This proactive step can significantly reduce the concentration of fumes.

It’s also wise to plan ahead concerning the curing time. Most spray foams require a curing period where they emit higher levels of fumes. During this time, limit occupancy in the area being treated and allow the foam sufficient time to cure fully before entering the space again.

| Step | Details | Safety Precautions |

|---|---|---|

| Surface Preparation | Clean and dry the area thoroughly. | 🏠 Ensure the area is free from moisture. |

| Application | Start spraying from the bottom up. | 😷 Wear respiratory protection. |

| Ventilation | Open windows and use fans if indoors. | 🚪 Keep the space clear for airflow. |

| Curing Time | Allow foam to cure before re-entry. | ⏳ Avoid the area until fully cured. |

Maximizing Benefits of Spray Foam Kits for Home Insulation

When used correctly, DIY spray foam kits can significantly enhance home insulation. The expanded foam creates an airtight seal that effectively minimizes thermal bridging and air leakage, making homes more energy-efficient. This not only leads to lower utility bills but also contributes to environmental sustainability by reducing energy consumption.

Furthermore, the insulation properties of spray foam can assist in soundproofing as well. Homeowners often overlook this benefit; the dense foam blocks external noise while preserving internal sound quality. It’s an exciting prospect for those looking to create a peaceful home environment.

Long-Term Considerations

While the immediate benefits of DIY spray foam kits are apparent, long-term considerations must also be taken into account. Over time, insulation integrity can be affected by moisture or structural changes. Homeowners should regularly inspect areas treated with spray foam to ensure effectiveness remains intact.

For best results, consider combining DIY spray foam with other insulation types in your home. This multi-layered approach can help maximize thermal performance while balancing potential drawbacks.

What is DIY spray foam useful for?

DIY spray foam kits are primarily used for home insulation, sealing gaps and cracks to improve energy efficiency and reduce heating and cooling costs.

How long do I need to stay out of an area after spraying foam?

It is advisable to stay out of the area for at least 24 hours to ensure proper curing and ventilation, minimizing the inhalation of any harmful fumes.

What type of protective gear is recommended?

It is crucial to wear gloves, safety goggles, and a respirator when applying spray foam to protect against skin contact and inhalation of toxic fumes.