With the rising popularity of spray foam insulation, preparing the installation area is crucial for a successful outcome. Homeowners often focus on the benefits of spray foam, like energy efficiency and moisture control, but the installation process is equally vital. Proper preparation ensures that the insulation adheres correctly and offers lasting performance. This article dives into the essential steps that installers take to prepare homes before spraying foam insulation, showcasing how these measures contribute to effective installation and, ultimately, a comfortable living environment.

Brief

- 🏠 Thorough area clearing to optimize workspace.

- 🧹 Surface cleaning to ensure adhesion.

- 🔌 Identifying and marking electrical outlets.

- 🌬️ Ensuring proper ventilation for safety.

- 🦺 Utilizing protective gear for installers’ safety.

Identifying Areas for Spray Foam Installation

Before the crew even arrives, one of the initial steps is assessing which areas of the home will receive the spray foam treatment. Common places include attics, crawl spaces, and garages. Each location has specific needs and considerations that must be addressed before installation can begin.

For instance, attics often contain various structural elements, electrical work, and sometimes even plumbing. Installers typically conduct a preliminary inspection to identify any obstacles or special features that could complicate the spraying process. They need to ensure free access to these spaces, which means homeowners should take the time to clear out any obstructions. This is especially important for driveways, hallways, and stairwells, making sure crew members can conveniently transport their equipment.

In addition to space clearance, understanding the layout of utilities and existing insulation is essential. Each home is unique, and recognizing these features helps avoid any mistakes that could cause issues in the future. For example, if there’s existing insulation in the attic, it may need to be removed or adjusted to ensure compatibility with the new foam. This ensures a smooth application process, avoiding any gaps or uninsulated areas that could compromise the insulation’s effectiveness.

Clearing the Space Effectively

Clearing the space for spray foam insulation is one of the most straightforward yet effective measures to improve the installation process. Homeowners are often advised to remove as many items as possible from the target areas. This not only gives installers ample room to work, but it also protects personal belongings from accidentally getting sprayed with foam or covered in dust during the installation.

Different strategies can make this task easier. For example, organizing items into boxes or using a storage facility temporarily may help maintain an ordered environment. Additionally, understanding the layout of the installation area allows for better organization, thus speeding up the process once the installers arrive. When everything is clear, the team will have a more efficient setup and will be able to focus on doing the work rather than navigating around obstacles.

Make sure to communicate with the installation team about any sensitive items that may require extra care. They can suggest protective coverings or other measures to safeguard these belongings during the process. Not only does this foster a pleasant working relationship with the contractors, but it also ensures that the installation goes off without a hitch.

Surface Cleaning for Optimal Adhesion

After clearing the space, surface cleaning becomes a necessity. It may seem trivial, but this step plays a key role in ensuring that the spray foam adheres appropriately to surfaces. Dust, dirt, and other debris can greatly affect the performance of foam insulation. An effective surface cleaning methodology often involves vacuuming and wiping down walls and ceilings in attics and crawl spaces to remove any dust that may linger.

Installers might also conduct a moisture check in these areas; damp surfaces can hinder adhesion, compromising the insulation’s integrity. If moisture is detected, further steps, such as ventilation adjustments or dehumidifiers, may be necessary before installation can proceed. By checking for moisture and cleaning surfaces, installers ensure the spray foam creates a hermetic seal, which is essential for energy efficiency and preventing air infiltration.

Importance of Temperature Control

Another factor contributing to proper application involves temperature control in the workspace. Spray foam performs best when temperatures are within a specific range. If it’s too cold, the foam may not expand properly, while excessive heat can make it cure too quickly, leading to other complications. To combat this, installers often use heaters or fans in stuffing attics on chilly days to maintain an optimal work environment.

Identifying and Marking Electrical Outlets

Before the spraying begins, it’s important to identify all electrical outlets in the work area. Failure to do so can result in serious safety hazards, including covering outlets that could lead to overheating or a fire risk. Installers often ask homeowners to help note any outlets that are hard to find, ensuring that every outlet is accounted for and properly marked.

Using proper measures to handle the electrical components is crucial. Installers might use masking tape or special coverings to shield the outlets, preventing foam from entering them. This step not only ensures a safer working environment but also preserves the integrity of the electrical system in the home. Clearly marking outlets helps streamline the installation, allowing for thorough coverage while avoiding unintended obstructions.

Ventilation and Safety Measures

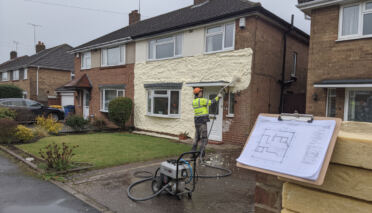

Ensuring proper ventilation in the workspace is another essential step before installation. Spray foam can emit fumes that, if inhaled in a poorly ventilated area, can pose health risks. Before commencing the application, installers take measures to setup adequate ventilation to keep air circulating. This is usually done by opening windows and using fans to facilitate air movement. Additionally, every installer should wear the appropriate safety gear, which includes gloves, goggles, and masks, to protect themselves from accidental exposure to chemicals during the installation process.

Safety instructions should be clear and adhered to by everyone present during the installation. A coordinated effort ensures that the installation goes smoothly, allowing the team to perform their work efficiently while maintaining the safety of everyone involved. Once proper ventilation is in place and safety measures have been observed, installers can proceed with confidence.

Final Inspection Before Spray Foam Application

Before commencing the spray foam application itself, a final inspection is crucial. This double-check ensures everything is in order, from surface preparation to safety protocols. Installers typically walk through the prepared areas, confirming that all steps have been completed as planned. They will also revisit the electrical outlets marked prior to installation, ensuring that all are ready for coverage.

This last-minute inspection serves two key purposes: firstly, it prevents potential mishaps during the installation process. Secondly, it provides an opportunity to make any last-minute adjustments before making the big leap into application. If any issues arise during the inspection, they can be addressed, ensuring that the installation will proceed without complications. The last thing anyone wants is to encounter problems midway through the installation.

What should I do to prepare my home for spray foam insulation?

You should clear out personal belongings from the installation area, conduct surface cleaning, identify electrical outlets, and make sure proper ventilation is established.

How long does the preparation process take?

Preparation generally takes a few hours to a full day, depending on the state of the area and the size of the installation.

Is spray foam insulation safe for my home?

Yes, when installed properly, spray foam insulation is safe. Following the preparing steps mitigates any risks.