In the ongoing quest for energy efficiency in homes and commercial buildings, the debate over insulation materials has become more significant than ever. Among the leading contenders are foam insulation and fiberglass, each boasting unique advantages and applications. As property owners increasingly seek solutions to curb energy costs, understanding the nuances between these two types of insulation, particularly their R-values, is crucial. In 2025, while technology and materials continue to evolve, R-value remains a cornerstone metric for assessing insulation performance, helping builders and homeowners make informed decisions that will enhance thermal comfort and energy efficiency.

So what is the R-value, and why does it matter? R-value is the measure of thermal resistance used in the building and construction industry. It indicates how well insulation materials can resist heat flow—the higher the R-value, the better the insulation’s effectiveness at keeping buildings warm in winter and cool in summer. Foam insulation generally ranks higher in R-value compared to fiberglass, often resulting in thinner layers being required to achieve similar thermal performance. As we dive into the specifics of the R-values associated with foam insulation versus fiberglass, we’ll explore the characteristics, benefits, and the most common applications for each material.

Understanding R-Value: The Measure of Insulation Effectiveness

R-value, in simple terms, represents the effectiveness of insulation materials. It measures how well these materials resist heat flow. This measurement is critical because a higher R-value usually indicates better insulation capabilities. For example, closed-cell foam tends to have a substantially higher R-value compared to open-cell foam, making it particularly suitable for commercial buildings that need to maintain consistent temperature levels.

- 🌡️ Greater Energy Savings: A high R-value can lead to significant reductions in heating and cooling costs.

- 📏 Thinner Insulation Layers: For applications where space is a constraint, such as attics or narrow walls, thin insulation with high R-value is essential.

- 🕒 Long-Term Performance: Properly installed insulation with high R-values is less susceptible to thermal drift, meaning it retains its effectiveness over time.

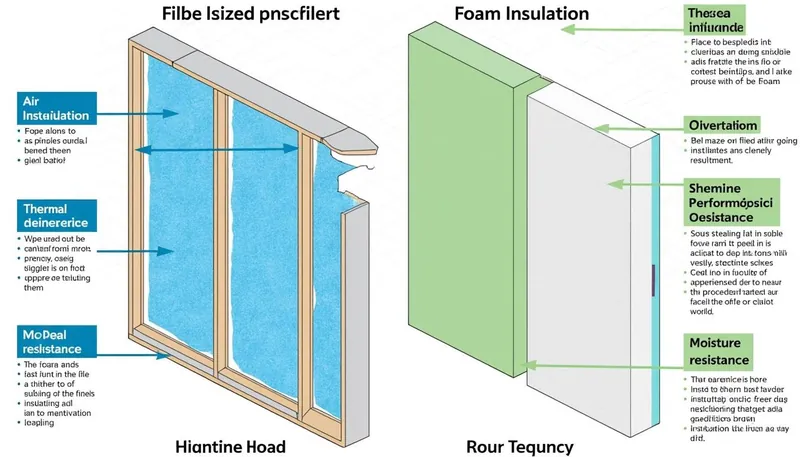

When comparing materials, foam board insulation is a major player because of its closed-cell structure, which traps insulating gases more effectively than fibrous materials or open-cell options. Moreover, the way insulation is installed also impacts its effectiveness. Unlike fiberglass that is battened in, spray foam insulation expands to fill gaps, creating an air-tight seal that significantly minimizes air leakage.

Important R-Values of Common Insulation Types

| Insulation Type | R-Value per Inch | Typical Applications |

|---|---|---|

| Closed-Cell Spray Foam | R-6.0 to R-7.0 | Commercial roofs, walls |

| Open-Cell Spray Foam | R-3.5 to R-4.0 | Interior walls, soundproofing |

| Fiberglass Batts | R-2.9 to R-3.8 | Attics, interior walls |

| PIR Foam Board | R-6.0 to R-7.0 | Exterior walls, roofs |

Foam Insulation vs. Fiberglass: A Comprehensive Comparison

Both foam and fiberglass insulation are widely used in construction but serve different purposes based on their respective properties. At the core of the comparison are R-value, installation methods, cost, and performance aspects like air sealing and moisture resistance. Here, we will pit foam insulation against fiberglass across these crucial dimensions.

Cost Considerations

When comparing the upfront costs, fiberglass insulation is typically less expensive to install. However, considering the long-term energy savings generally achieved with foam insulation, many find that the initial investment pays off significantly over time. For instance, while the installation of PIR foam boards can be about 20% more expensive than that of fiberglass, the superior insulation performance (15-20% higher R-value) can reflect positively in the utility bills.

Installation Methods

The installation methods differ significantly between these two materials. Fiberglass batts or rolls are relatively straightforward to install, making them a go-to choice for DIY enthusiasts. In contrast, foam insulation requires a professional, especially for spray foam instantiation. The foam is sprayed in place, expanding to fill irregular spaces, therefore providing an excellent air seal. This air-tight barrier is crucial in preventing energy wastage.

Moisture Resistance and Air Sealing

Foam insulation excels when it comes to moisture resistance. The expansion nature of spray foam forms an impermeable barrier that wards off moisture, dramatically reducing the risk of mold growth. Conversely, fiberglass can absorb moisture, compromising its R-value over time and leading to potential structural issues. As we look further into the qualities, we see that both insulation materials have their places but for moisture-prone environments, foam insulation stands out as the superior choice.

- 🛡️ Air Leakage Reduction: Foam insulation dramatically minimizes air leaks compared to fiberglass.

- 💧 Mold Prevention: Foam insulation serves as a moisture barrier, thus minimizing mold risks.

- 🏡 Thermal Performance: Foam generally maintains R-value better in humid conditions.

Key Advantages of Choosing Foam Insulation

As we wrap up the specifics, it’s evident that foam insulation brings several critical advantages to the table when compared to fiberglass. Understanding these can provide valuable insights for property owners making insulation choices.

Energy Efficiency

Foam insulation presents a high R-value at a lower thickness, allowing homeowners and builders to save precious living space without sacrificing performance. In the case of spray polyurethane foam (SPF), it not only acts as an insulator but also as a structural element, greatly enhancing the overall strength of walls.

Application Flexibility

Whether it’s an irregular surface or a tight space, foam insulation adapts perfectly to various construction requirements. This versatility stands as a major selling point. Companies like Owens Corning, Johns Manville, and Kingspan provide a range of foam products designed to meet diverse needs. From attics to crawl spaces or commercial buildings, the foam tackles insulation challenges head-on.

Reduced Energy Costs

The long-term energy cost savings from foam insulation cannot be overstated. Over time, the return on investment can be substantial, considering reduced temperature fluctuations and lower energy demands. 🤓 However, property managers and builders should always weigh the initial installation costs against long-term benefits.

Broader Applications and Industry Trend Insights

The landscape of insulation continues to evolve alongside new construction standards and energy efficiency regulations. As of 2025, there’s a noticeable shift toward materials that boast not only high R-values but also sustainability features. Products from manufacturers such as Dow, ROCKWOOL, and Atlas Roofing are increasingly meeting these burgeoning needs with cutting-edge insulation solutions that serve the dual purpose of energy efficiency and environmental responsibility.

Emerging Trends in Foam Insulation

When discussing foam, it’s crucial to highlight innovations that have made modern foam insulation more eco-friendly. Advanced formulations can incorporate recycled materials, which are effective in achieving R-values without the environmental burden. The industry is gradually moving towards ** »green » insulation options that meet the rigorous standards for safety and environmental impact, which means more options for consumers.

Navigating Regulatory Requirements

Your insulation choice should also factor in local building codes and regulations that are shaping how insulation materials are utilized. Many new regulations emphasize energy-efficient materials, prompting builders and developers to rethink their traditional choices. They should check for certifications and compliance from reputable organizations, ensuring long-term performance and reliability.

- 🇺🇸 Local Codes Compliance: Always ensure your insulation meets local building standards.

- 💡 Innovative Technologies: Stay ahead by choosing the latest advancements in insulation materials.

- 🌱 Sustainable Options: Look for eco-friendly products that don’t compromise on performance.

What is the R-value of typical fiberglass insulation?

Fiberglass insulation typically has an R-value ranging from R-2.9 to R-3.8 per inch.

How does closed-cell foam compare to open-cell foam?

Closed-cell foam generally offers higher R-values (R-6.0 to R-7.0), while open-cell foam typically ranges from R-3.5 to R-4.0.

What are the benefits of foam insulation over fiberglass?

Foam insulation provides better air sealing, higher R-values per inch, and superior moisture resistance compared to fiberglass.

Which insulation is best for moisture-prone areas?

Foam insulation is ideal for moisture-prone areas due to its resistance to moisture and mold growth.

Can you install fiberglass insulation yourself?

Yes, fiberglass insulation can be installed as a DIY project by homeowners, while foam insulation usually requires professional installation.