In the ever-evolving world of modern construction, insulation plays a vital role in enhancing energy efficiency and occupant comfort. Foam insulation has gained popularity for its superior thermal performance and versatility compared to traditional materials. However, the question remains: is foam insulation suitable for all types of buildings? This article takes an extensive look at the various types of foam insulation, their applications, and the performance variability across different building types, ensuring you are well-equipped to make an informed decision.

Brief

- 🔍 Foam insulation types include spray foam, pour foam, can foam, injection foam, and foam board.

- 🏠 Each type serves different applications and building structures, from residential homes to commercial buildings.

- 💡 Open-cell versus closed-cell foam impacts moisture management and thermal efficiency.

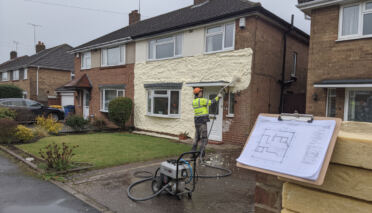

- 🛠️ Professional installation is recommended for certain foam types to ensure effectiveness.

- 🌱 Major brands like Owens Corning and DuPont provide trusted foam insulation solutions.

Understanding Foam Insulation Types

When diving into the realm of foam insulation, it’s crucial to grasp the differences between the various types. There are primarily five notable categories: spray polyurethane foam, pour polyurethane foam, can foam, injection foam, and foam board. Each type has its unique properties, making them suited for specific applications while impacting thermal performance differently.

| Type of Foam Insulation | Application | Typical R-Value |

|---|---|---|

| Spray Polyurethane Foam | Roofs, walls, attics | R-6 to R-7 per inch |

| Pour Polyurethane Foam | Masonry structures, wall cavities | R-6 to R-7 per inch |

| Can Foam | Minor gaps, cracks, windows, doors | R-3.6 to R-4.2 per inch |

| Injection Foam | Retrofits | R-3.6 to R-4.2 per inch |

| Foam Board | Basements, roofs, and exterior walls | R-3.6 to R-6.5 per inch, depending on type |

Let’s target each category to illuminate their distinct applications:

Spray Polyurethane Foam

Spray foam insulation is a result of a chemical reaction between isocyanate and polyol. It is applied using a spray gun, allowing it to expand on contact and fill cavities thoroughly. The two types here are open-cell and closed-cell, each with unique attributes.

- 💨 Open-cell foam is light, flexible, and has a lower density which allows moisture to permeate but offers fantastic sound dampening.

- 🧱 Closed-cell foam is denser, provides better thermal insulation, and acts as a moisture barrier, making it ideal for exterior walls and roofs.

Pour Polyurethane Foam

Pour foam acts similarly to spray foam but is dispensed differently. It arrives in a liquid state and expands into foam after application. It’s great for insulating concrete blocks and masonry due to its density and high moisture resistance.

Using pour foam can significantly enhance thermal performance, particularly in commercial applications where moisture control is paramount. This product type exemplifies how specific applications determine the best insulation method.

Foam Board Insulation: The Rigid Performer

Among the various types of foam insulation, foam board insulation stands out as a rigid option, commonly employed for insulating roofs, attics, and walls primarily during new construction or renovation phases. Foam board options include expanded polystyrene (EPS), extruded polystyrene (XPS), and polyisocyanurate (polyiso).

| Type of Foam Board | Moisture Resistance | Typical R-Value |

|---|---|---|

| Expanded Polystyrene (EPS) | Moderate | R-3.6 to R-4.2 per inch |

| Extruded Polystyrene (XPS) | High | R-5 per inch |

| Polyisocyanurate (Polyiso) | High | R-6 to R-6.5 per inch |

These options cater to different needs based on applications, environmental conditions, and budget. In fact, many contractors recommend using polyiso board for high R-value performance combined with moisture resistance, making it a staple in commercial settings.

Moisture management is critical in building insulation, as materials like EPS are less effective in wet conditions. Thus, selecting an appropriate foam insulation should consider these factors deeply.

Common Applications for Foam Board Insulation

The flexibility and strength of foam board insulation make its applications varied:

- 🏛️ Insulating foundations and basement walls during new builds or renovations.

- 🏠 Used behind siding to aid climate control in existing homes.

- 🧼 Ideal for insulating crawl spaces and moisture-heavy areas.

- 🏢 Frequently employed in commercial metal buildings.

Expert Considerations: Applying Foam Insulation

As much as one can appreciate the benefits of foam insulation, the installation process should be treated with caution. While products like can foam may be suitable for DIY projects, professional installation is vital for types reliant on proper application techniques, like spray foam and injection foam. Considerations also include local building codes, safety regulations, and more.

Here are a few key recommendations:

- 🔧 Always consult a professional contractor for complex installations.

- 📜 Ensure compliance with local building regulations and codes.

- 🧴 Select quality products from reputed brands such as Owens Corning or Johns Manville to ensure reliability and performance.

Additionally, addressing environmental factors, such as whether a building is susceptible to moisture or extreme temperatures, will play a significant role in determining the appropriate insulation type.

Understanding Performance Variables Across Building Types

While foam insulation offers tremendous benefits, suitability varies across different building types. For example, spray foam may excel in residential homes due to its superior airtight sealing properties but may be excessive for small outbuildings where other insulation types would suffice.

Additionally, commercial buildings with larger, open spaces often require insulation with robust moisture control, meaning closed-cell foam products such as those from BASF or Dow Building Solutions are typically recommended to withstand humidity levels.

Considerations for building types also include:

- 🏡 Residential Buildings: Spray and injection foams typically provide the best energy efficiency.

- 🏢 Commercial Buildings: Closed-cell spray foam and rigid boards provide durability and moisture resistance.

- 🏡 Historical Buildings: Injection foam can retrofit existing structures without major renovations.

In summary, the choice of insulation should correspond to the building’s structure, local climate, and specific architectural design. Adapting your insulation strategy based on these variables will create a more comfortable, energy-efficient environment.

What is the best type of foam insulation for residential buildings?

Spray polyurethane foam is often considered the best option for residential buildings due to its high R-value and excellent air-sealing properties.

Can I install foam insulation myself?

While some foam insulation types like can foam are suitable for DIY projects, others such as spray foam require professional installation for optimal performance.

How much does foam insulation cost?

The cost of foam insulation varies widely based on the type of product and installation costs; typically between $1 to $3 per square foot.

Is foam insulation eco-friendly?

Some foam insulation products are eco-friendly, such as those containing water-blown agents instead of hydrofluorocarbons.

How much R-value do I need for my building?

The required R-value varies by climate zone and building type; consulting local building codes can provide specific requirements.